Waterloo Aerial Robotics Group

Mechanical Project Manager

- Managed design of key drone components including dual-axis

camera gimbal, landing gear, and various electronics cases

- Designed casing for custom lithium ion battery pack

- Vacuum infused carbon fibre panels for frame of 14 kg drone

Mechanical Team Member

- Designed drone casing for various PCBs and landing gear in Solidworks

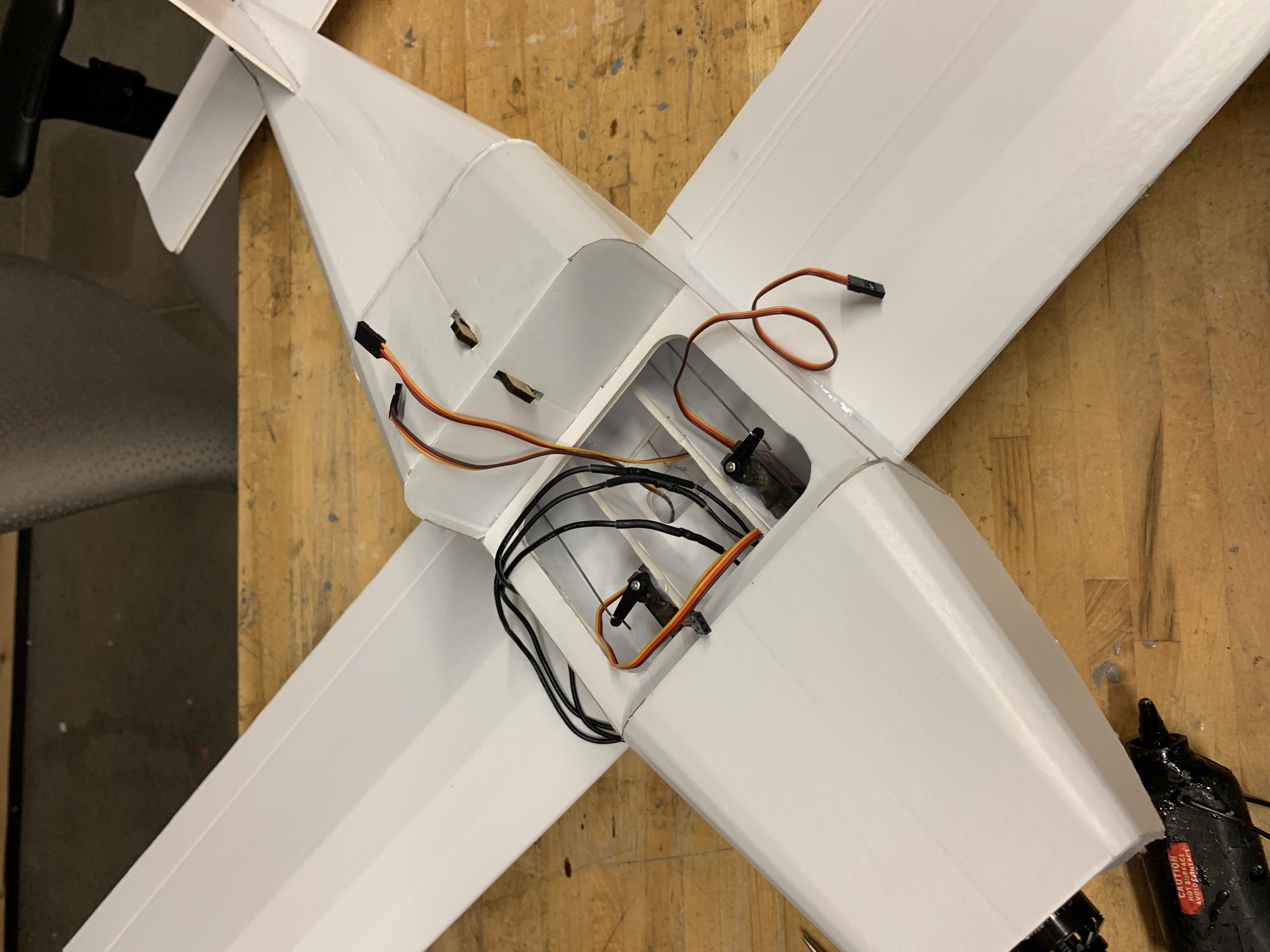

- Machined and assembled fuselage and wings for fixed-wing airplane by milling

aluminum, laser cutting wooden ribs, and applying ultracote for light wing skin

- Performed wet carbon fibre layup for drone side panels

- Designed IR camera and Raspberry Pi mount for existing frame, with rubber

grommets to be friction fit onto drone

- Aided in assembly of 3.8 kg fixed wing plane by wrapping wings in ultracote,

modifying landing gear, and harnessing electronics

H2Ontario - General Contractor

Laborer

- General work at Pumping Station in Waterloo, Wastewater

Treatment Plant in St Marys, and Water Treatment Plant in Port Dover

- Fused HDPE pipe system over 200 ft long, providing temporary bypass of

plant's headworks building and aided in construction of steel piping

system for flocculation tanks

- Used Leica Total Station to layout road marks, curbs, hydro, and building

components, as well as estimate volumes of dirt piles

- Used drone for site photography and to get images of rooftop layouts

- Filled air filter tank with 93 000 kg of media, worked on PVC pipe humidifier

system for filter